Breath Spray OEM/Manufacturing/Custom

Our Service

Formulation Customization

We tailor stable formulations and atomization performance for breath freshening sprays based on target users’ requirements for portability, flavor intensity, and rapid freshness.

Private Label Breath Spray

We provide comprehensive private label solutions for brands, including packaging design, label production, and formulation fine-tuning, helping you quickly establish unique brand selling points.

Contract Manufacturing

Utilizing mature spray filling lines and stringent quality control systems, we undertake medium-to-large-scale production of breath freshening sprays according to client specifications, ensuring consistent delivery and quality.

Breath Spray Wholesale

We supply multiple ready-to-sell breath freshening spray options with ample inventory and competitive pricing, making them an ideal choice for distributors seeking rapid restocking and promotional opportunities.

Popular Breath spray Manufacturing Service

Cinnamon breath spray

Cinnamon Breath spray, an innovative oral care product with natural Mutual Leaf Melaleuca alternifolia oil, Tea Leaf Extract, Myrrh Oil and Cinnamon Oil as the main ingredients, brings you a unique oral cleaning experience. We offer cinnamon scent, so you can enjoy fresh breath and face life with confidence.Cinnamon Breath spray effectively removes oral odors, improves the oral environment, takes care of dental health, and lets you enjoy a good mood every day.

Peppermint breath spray

Peppermint Breath Spray, an innovative oral care product with natural PEG-40 hydrogenated castor oil and peppermint oil as the main ingredients, brings you a unique oral cleaning experience. Available in mint flavor, Peppermint Breath Spray will help you enjoy a fresh breath and face life with confidence.Peppermint Breath Spray can effectively remove bad odors, improve the oral environment, take care of dental health, and help you enjoy a good mood every day.

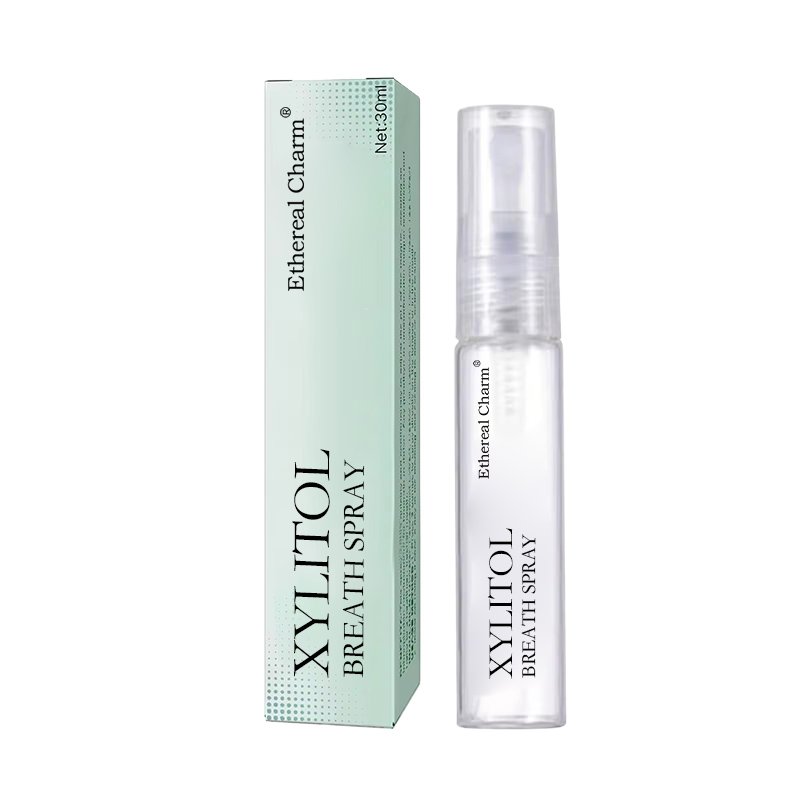

Xylitol breath spray

Xylitol Breath Spray, an innovative oral care product with natural xylitol as the main ingredient, brings you a unique oral cleaning experience. We offer fresh scent, so you can enjoy fresh breath and face life with confidence.Xylitol Breath Spray can effectively remove oral odor, improve the oral environment, take care of dental health, so that you can enjoy a good mood every day.

Get a one-stop solution

Phone: 0591-85104888

Email: peter@ruiqigo.com

Address: No.27 Yangting Road, 3TOP Industrial Park, Taiyuan Village, Chengfeng Town,Yongtai County, Fuzhou, Fujian, China, 350700

Privacy:

As with all of our clients, confidentiality remains of paramount importance to demonstrate our commitment to customer service. You can fill out the application form with confidence that your form will only be used for quote purposes.

Ready to get started?

If your project requires more immediate assistance, please give us a call or email and we will respond to you as quickly as possible.

Thanks for connect with us. Ask me anything.

Capabilities of 3TOP Breath spray Manufacturer

-

Sterilization room

-

Raw material warehouse

-

Batching room

-

Dispensing room

-

Filling line

-

Carton coding

-

Packaging line

- Working Procedure

- Function Characteristics

Dressing, hand washing, and drying, into the air shower room disinfection.

The clean room ensures that every employee entering the room meets the operating standards through strict sterilization steps.

- Working Procedure

- Function Characteristics

1. Material Purchase

All raw material applications always have a requisition form, the warehouse manager according to the requisition form for verification according to the monthly material requirements of the master plan for the system application.

2. Material into the warehouse process

Warehouseman according to the procurement contract and delivery list for inventory, verification, material placed in the area to be inspected, and in a timely manner to do a good job of material identification, labeled to be inspected. Then warehouseman according to the actual number of input computer ERP system prints out the receipt of materials signed by the receipt of joint delivery or purchaser and, at the same time, the inspection of the joint to the inspector of the material the factory inspection.

The factory inspector received the inspection sheet and the timely inspection of the materials in the batch.

The material acceptance of qualified, the inspector in the receipt of materials on the signature to confirm; the inspector will be qualified and non-qualified products were labeled, clearly distinguishable.

Materials placed in the designated partition location.

1. Safe and stable reserve

Raw material warehouses can provide safe and stable material reserves for production and ensure the stability and continuity of enterprise production capacity. The distribution of raw materials in the LS warehouse requires flexibility and timely supply. When the production line needs raw materials, the requirements of raw material reserves are sufficient, to be able to timely deployment and supply to the production line, to meet the production needs.

2. Ensure the quality of production

Raw material warehouses can ensure the stability and reliability of the quality of raw materials needed for production so that enterprises in the production chain to ensure product quality and competitiveness.

3. Reduce production costs

Raw material warehouses in ensuring product quality at the same time, can reduce production costs, and improve corporate profitability and market competitiveness. Characteristics: Adopting XXX method to make the stored materials free from moisture, heat, damage, and so on. Set up an anti-theft alarm system, fire alarm equipment, fire prevention measures, and other measures for the warehouse to ensure the safety and stability of raw material reserves.

- Working Procedure

- Function Characteristics

1. Receive the outgoing task list

According to the production plan and recipe list to prepare the required materials.

2. Batching

Accurately weigh the components and record the data; add the matched materials into the mixing equipment according to the specified order and monitor the mixing process.

3. Cleaning

Clean up the site in time after completing the dosage, keep the environment neat and clean.

4. Update the inventory

At the same time, update the real-time status of the inventory of material consumption, to ensure that the production is carried out smoothly.

Responsible for accurately batching, weighing, and mixing raw materials to ensure consistency and accuracy of each recipe, aiming to ensure accurate batching of materials and efficient inventory management.

- Working Procedure

- Function Characteristics

1. Equipment sterilization

Sterilize the equipment before operation to ensure the safety of production.

2. Mixing

According to the formula, put different raw materials into the stirring reaction pot for mixing, after stirring and other processing, make all kinds of raw materials reach the condition of a chemical reaction.

3. Heating and cooling

The mixture with an adjusted formula is heated and cooled, through heating, it can make certain ingredients in the mixture dissolve and react better, and strengthen the stability of the product.

4. Pumping

The processed semi-finished products will be pumped into the assembly line after inspection to make the next step of molding and packaging.

Function: Make semi-finished products.

Features:

1. Reduce airborne dust

The clean room uses high-efficiency purification systems, operating tables, floors, walls, and other materials that can effectively reduce airborne dust. By purifying the air, it can ensure that the chemical components and microorganisms are fully protected during the production process, preventing external particles from mixing into the products, and ensuring the high quality and stability of the products.

2. Prevent biological pollution

In the production process, too many microorganisms can easily cause fermentation, spoilage and other problems in the production process. However, in the clean room, disinfection lamps, differential pressure control systems, UV lamps and other equipment will be used, which can effectively kill microorganisms, and can prevent pollutants from the outside from entering the workshop.

3. Purify the air in the workshop

Clean room, often using air purification equipment and tightly closed structure, in order to purify the air in the workshop, and raise the pressure in the workshop. By isolating the workshop from the outside world, the cleanliness of the production process is ensured.

- Working Procedure

- Function Characteristics

1. Material preparation

Insert the container to be filled into the work box and make sure the liquid storage barrel is full of liquid to be filled.

2. Power supply connection and startup of the filling machine

Turn on the external power supply, set the machine power switch to ON position, and the power indicator light will be on to indicate that the power supply is on.

3. Filling volume adjustment

According to the total amount of each bottle filling, adjust the screws on the crank to ensure that the amount of liquid flowing out of each filling head is the set amount.

4. Filling speed control

Rotate the knob of the filling speed control board to the appropriate position, and then toggle the switch on the filling speed control board to the open position to control the filling speed.

5. Start filling

Close the filling speed regulator board switch, reset the total metering pump output pipe, and then toggle the filling speed regulator board switch to the open position, the total metering pump starts to work, and enters into the liquid dispenser through the total metering pump output pipe, and the liquid is dispensed through the liquid volume micro-adjustment and outflow from the syringe to complete the filling.

Function: Filling the semi-finished products with the set amount of filling and the form of packaging, automatically filling the semi-finished products accurately into the corresponding packaging, and then transferring them to the next process by conveyor belt.

- Working Procedure

- Function Characteristics

Spray the carton with the corresponding barcode through the inkjet printer

Function: Non-contact marking of the products, clear and fast.

- Working Procedure

- Function Characteristics

1. Preparation

Before starting the packaging, you need to prepare the required packaging materials and equipment, such as cartons.

2. Product input

The products are transported from the upstream production line to the assembly line packaging line through the conveyor belt.

3. Packaging operation

The products are sleeved, shrunk, coded and boxed.

4. Packing and sealing

Finally, the packed products are sealed.

Function: Packaging of semi-finished products into a complete product. Characteristics: One-way operation, strict process, fast speed.

3TOP Breath spray Factory Features

-

Complete Workshop and Processes

Complete Workshop and Processes

3TOP has advanced production facilities and complete manufacturing processes to ensure that every step from raw materials to finished products meets the highest standards.

-

R&D Strength

R&D Strength

3TOP's R&D team cooperates with renowned universities and laboratories to continuously promote product innovation and technological advancement.

-

Purely Personalized Customization

Purely Personalized Customization

With a professional R&D team, we provide full-process customization services from testing to production to ensure the uniqueness and competitiveness of our products.

-

Lower MOQ

Lower MOQ

Flexible production strategy to meet diversified needs from small to large quantities.

-

Quality Control

Quality Control

Strict quality control process at the source factory to ensure product consistency and reliability.

-

Climate Adaptability

Climate Adaptability

Customized products for different regional climate characteristics to meet the needs of the global market.

-

Production Apacity and Scalability

Production Apacity and Scalability

Large-scale production capacity and the ability to quickly respond to market changes and expand production capacity.

-

Environmentally Friendly Packaging Materials

Environmentally Friendly Packaging Materials

Use 100% biodegradable and recyclable environmentally friendly materials to minimize the impact on the environment.

-

Fast Sample Service

Fast Sample Service

Provide free samples and promise to send them out quickly within a week, far exceeding the industry standard.

-

Customized Packaging Design

Customized Packaging Design

Provide personalized packaging design and suggestions to enhance product market appeal.

3TOP Breath spray OEM/ODM Advantage & Benefits

-

1

Customized breath spray formula:

3TOP Breath Spray offers a variety of flavors and formulas to meet different market needs, and supports customers to customize exclusive products to enhance brand personality. -

2

Efficient and fresh breath:

Our breath spray uses unique ingredients to quickly eliminate bad breath and improve user experience. It is suitable for B-end customers such as catering and hotels. -

3

Portable design:

The small and lightweight packaging is convenient for consumers to carry at any time. It is suitable for use in various commercial occasions, such as meetings, travel, etc., to improve customer satisfaction. -

4

High-quality raw materials:

The products use natural ingredients to ensure safety and non-irritation, meet the high standards of B-end customers for product quality, and enhance brand trust. -

5

Strong production capacity:

3TOP has advanced production equipment and rich production experience, and can quickly respond to the large-volume order needs of B-end customers to ensure timely delivery. -

6

Professional ODM service:

Provide professional OEM/ODM services for B-end customers, from design to production, full assistance, to help customers quickly enter the market. -

7

Market research support:

We provide analysis of market trends and consumer preferences to assist B-end customers in formulating effective product strategies and enhancing market competitiveness. -

8

Multiple packaging options:

Provide diversified packaging solutions to meet the brand positioning needs of different customers and enhance the product's visibility in the terminal market. -

9

Sustainable development plan:

3TOP pays attention to environmental protection in the production process and uses recyclable packaging materials, which is in line with the core value of modern enterprises for sustainable development and enhances the brand image. -

10

Perfect after-sales service:

We provide B-end customers with comprehensive after-sales support, including product quality assurance, market feedback processing, etc., to ensure customer satisfaction and continuous product improvement.

Certificates

Start your Breath spray bussiness with our support

-

Daniel Lewis

Having teamed up with 3TOP for our oral spray line, I can genuinely say it's been a partnership that's as refreshing as the product itself. Their custom manufacturing service has been nothing short of stellar, allowing us to bring to market a spray that's both effective and a delight to use.

The team at 3TOP has a real knack for getting into the nitty-gritty of what consumers look for in oral care. Their commitment to quality is evident in every canister, and their ability to cater to our specific requests has been truly impressive. From the formulation that leaves a pleasant taste to the packaging that's as sleek as it is sustainable, 3TOP has been with us every step of the way.

What I value most is their customer service. They've been incredibly responsive, always ready to discuss our ideas and turn them into a reality that resonates with our audience. Their proactive approach to addressing any concerns has made the entire production process a breeze.

In essence, 3TOP's dedication to excellence, their innovative approach, and their exceptional service have made them a trusted partner in our journey to provide top-notch oral care. We're thrilled with the results and look forward to continuing our collaboration. -

Laura Smith

Working with 3TOP on our oral spray has been a truly delightful experience. Their custom manufacturing capabilities have enabled us to offer a product that not only meets but exceeds our customers' expectations for freshness and effectiveness.

The level of expertise at 3TOP is apparent in every aspect of the oral spray, from the invigorating blend of flavors to the precise delivery system that ensures a consistent spray every time. Their attention to detail is second to none, ensuring that our brand's standards for quality are upheld.

One of the most commendable aspects of our collaboration has been their flexibility. Navigating the nuances of creating a unique oral care product can be challenging, but 3TOP has been more than accommodating, adjusting formulations and packaging with ease to align with our vision.

Moreover, their customer service is exemplary. The team at 3TOP is always on hand to offer support and guidance, making the production process seamless. Their willingness to go above and beyond to ensure our satisfaction has been a testament to their professionalism.

In summary, 3TOP's commitment to quality, their innovative spirit, and their outstanding customer service have made them a cherished partner in our oral care product development. We're excited about the future of our partnership and the innovative products we'll create together.

Guess you also want to ask

-

Do the oral sprays manufactured by 3TOP comply with international safety standards?

3TOP has strictly controlled this oral spray in accordance with international safety standards, so it can be defined from product quality and safety sides. For one thing, 3TOP adopts raw materials that meet international regulations; secondly, all the ingredients have to pass strict screenings to ensure that they are all harmless to the human body and do not contain any harmful chemicals. The natural components in the formula of the product not only refresh the breath but also are supportive of good oral healthcare, which reflects contemporary consumers’ interest from all over the world in safe and natural products.

It is the production process that follows the internationally recognized Good Manufacturing Practice standards. That is every link in the production process is very strictly controlled to ensure the finished product’s consistency and stability. The equipment’s cleanliness and the operators’ training are all very fine-tuned at 3TOP. This kind of strict management will effectively reduce the risk of product contamination during production and further guarantee the spray’s safety.

Furthermore, 3TOP's products have tailed the requisite international safety certifications to guarantee that they can meet relevant regulatory requirements in market consumption in different countries and regions. These include FDA certification and the pertinent EU cosmetic regulations, which make 3TOP's oral spray internationally well-regarded. Context: The original text is professional in its tone, with a formal register and informative purpose. This should be preserved in the rewriting.

Before fully launching it, 3TOP will subject the product to many rounds of safety and efficacy tests to prove that it will not evoke allergies or other discomfort while using. Since these include not only evaluations under laboratory conditions but also those with real users, they guarantee the product to be safe and efficient in the real sense of application. -

Does 3TOP provide customized services for oral sprays, including special formulations or packaging?

Yes, 3TOP customizes oral sprays through special formulations and packaging options. This flexibility enables customers to come up with products that are very specific to what the market is demanding or what the consumers’ preferences are.

Customized Formulations

In addition to the above, 3TOP offers various formulation options whereby customers can select proprietary flavors or active ingredients. Be it a particular flavor profile a customer is looking for, or some special benefits, like being all-natural or having extra health benefits, 3TOP works with its customers in creating products that are an expression of the customers’ brands for specified target consumers.

Tailored Packaging Solutions

Apart from the formulations that can be customized, 3TOP also offers varied packaging options. This kind of provision allows the customers to select packaging designs that are in sync with their brand image. The product, therefore, stands out in the competitive landscape. This may include packaging designs in different sizes, materials, or even different designs that can enhance the user experience and promote the product more effectively.

Comprehensive OEM/ODM Services

3TOP's commitment to custom: OEM and ODM. They hand-hold their customers through the process, right from developing the initial concept to delivering the final product, ensuring that the end product meets the quality standards set as well as the specifications of the client.

Market Research and Support

It also does market research and product development, helping the client understand what consumers want and the prevailing trends. This, therefore, enables a client to decide on product features that are marketable for assured success. -

How does 3TOP ensure the quality and consistency of our oral spray ingredients?

3TOP takes the quality and consistency of its oral spray ingredients very seriously and ensures that its products meet high standards through a number of measures.

First, 3TOP strictly screens suppliers to ensure that the raw materials used are from reliable sources and meet safety and quality standards. All raw materials are strictly tested when they arrive at the production facilities to ensure their high quality.

Second, 3TOP follows Good Manufacturing Practices (GMP) and implements strict quality control during the production process, including the management of the production environment, equipment maintenance and employee training. In addition, 3TOP also conducts real-time monitoring at each production link to ensure the optimization of production conditions to ensure product consistency.

Each batch of oral spray is subject to comprehensive testing, including microbiological testing and stability testing, to ensure the safety and effectiveness of the product during its shelf life. At the same time, 3TOP implements a comprehensive traceability system to ensure that the ingredients can be traced at every link from supplier to finished product, which helps to identify and resolve any quality issues in a timely manner.

Finally, 3TOP has a dedicated quality assurance team that oversees the entire production process to ensure that all products meet the established quality standards before they are launched on the market. These comprehensive measures have enabled 3TOP to establish a good reputation in the oral care industry and enhance consumer trust. -

What are 3TOP's strengths in oral spray product innovation?

3TOP has significant advantages in oral spray product innovation, including professional formulation development capabilities, strong R&D strength and flexibility to work closely with customers. Through in-depth market trend analysis and consumer insights, the company is able to quickly identify market gaps and launch high-quality products that meet demand. Its commitment to using high-quality ingredients, flexible production capabilities and sustainable development practices enable 3TOP to effectively respond to consumers' desire for natural and environmentally friendly products. In addition, rich regulatory knowledge ensures that products meet the health and safety standards of various markets, further enhancing consumer trust. These combined advantages make 3TOP stand out in a highly competitive market. -

What is 3TOP's production capacity and can it meet the demand for high volume orders?

3TOP has established production capabilities that are designed to be flexible and scalable, allowing the company to meet a wide range of order volumes, including high-volume requests. While specific figures regarding production capacity may vary and are often proprietary, 3TOP is generally equipped with advanced manufacturing technologies and processes that facilitate both small-batch and large-scale production.

Key Aspects of 3TOP's Production Capacity:

Scalability: 3TOP can adjust its production levels according to customer demand, making it suitable for both startup brands needing smaller initial orders and larger retailers requiring significant quantities.

Technology and Automation: The company invests in modern manufacturing technologies that enhance efficiency, reduce lead times, and ensure consistent product quality across different batch sizes.

Quality Control: Robust quality control processes are implemented throughout production to maintain high standards, which is crucial for meeting regulatory requirements and customer expectations.

Experience and Expertise: With a background in the industry, 3TOP possesses the necessary expertise to manage production effectively, even during peak demand periods.

Logistics and Supply Chain Management: A well-organized supply chain enables 3TOP to source ingredients and materials promptly, supporting its ability to fulfill high-volume orders in a timely manner. -

What kind of testing do oral spray products go through during the manufacturing process?

In manufacturing oral spray products, several tests are important to ensure product safety, efficacy, and quality. The following are a few of the tests that oral spray products typically undergo during the manufacturing process:

1. Raw material incoming检

For the first step of production, stringent quality inspection is imposed on raw materials. This includes sourcing and testing raw materials for purity, heavy metals, and microbial content to meet standards of safety and regulatory requirements. Only if the raw materials meet the inspection standard can they be put into the production process.

2. Test of physical and chemical properties

Other tests experienced by oral spray products include microbiological testing.

For such an impurity to be avoided, Spray effect testing is done as part of the manufacturing process.

Another important test content for the spray product is spray performance, including the atomization degree of the spray and speed of the spray, consistency of the nozzle, and spray range. These tests are to ensure uniform dosage and coverage so that each spray gives the desired effect.

3. Stability testing

Sensory evaluation includes the determination of taste and appearance. It is then assessed by a panel of tasters to give their opinion on it. A product with stable quality and attractive organoleptic properties is preferred by consumers.

Sensory evaluation is an assessment that revolves around the odor, taste, color, and touch feeling of a product. Such kind of tests could be done by a panel of professionals or consumer reviews to ensure that the product meets the market needs.

4. Clinical and Consumer Testing

At times, oral spray products are clinically tested besides being consumer-tested for safety and efficacy. In this way, feedback from users allows optimization of the formula and user experience. -

Are 3TOP's products priced competitively in the market?

We offer competitive prices by optimizing the production process and cost control, while guaranteeing the quality of our products. -

What is the lead time for 3TOP's oral spray products?

Our standard lead time is fast, and we also provide expedited service to meet customers' urgent needs. -

What after-sales services does 3TOP provide?

We provide a full range of after-sales services including technical consultation, product updates, market feedback and problem solutions. -

Does 3TOP adopt environmental protection measures in the production process?

Yes, 3TOP implements various environmental protection measures in the manufacturing of its oral spray. The company identifies the critical role sustainability and environmental responsibility play in the manufacturing sector. Some of these measures include:

Eco-Friendly Packaging

In the provision of its packaging solutions, the Company commonly employs environmentally friendly packaging solutions by using recyclable materials and reduced packaging size, therefore minimizing waste. This dedication to reducing the use of plastic and promoting recyclability helps lower the general environmental footprint of its products.

Energy Efficiency

The Company may implement energy-efficient technologies and practices in its manufacturing facilities. This includes the use of renewable sources of energy like solar and wind in machinery and optimization so the machinery uses less energy.

Waste Management

3TOP probably engages in responsible waste management by adopting recycling programs and minimizing the generation of waste during production. This helps the company reduce its environmental impact through waste management. ### 5. Water Conservation:

Being key to the production processes, water efficiency is very vital. This is to assume that 3TOP adopts technologies and practices that help in water consumption reduction and water recycling when feasible.

Regulatory Compliance

Both local and international environmental laws and regulations must be strictly observed by 3TOP to ensure that its production processes conform to them. In this way, the impact on the environment is not so negative.

Continuous Improvement and Innovation

The company intends to be involved in ongoing research and innovation that enhances its sustainability efforts. This includes acting upon new formulations and production methods: lowering environmental impact without product quality.

Employee Training and Awareness

3TOP likely focuses on its employees by incorporating environmental protection in its awareness campaigns and training programs, as a way of ensuring that at all levels of the organizational culture, there is a focus on sustainability.

2.jpg)

1.jpg)