Floss stick OEM and Manufacturing Service

Our Service

Formulation/Structure Customization

Tailored for diverse materials (waxed/unwaxed), filament gauges, and handle designs, our R&D team customizes material formulations and structural configurations to align with usage habits and durability requirements.

Private Label Services

We offer comprehensive private label solutions for dental floss picks, encompassing appearance and packaging design, label production, and product detail adjustments to help you rapidly build differentiated brand portfolios.

Contract Manufacturing

Leveraging mature floss pick production lines and rigorous quality control, we handle medium-to-large volume manufacturing, ensuring consistent floss tension, handle reliability, and on-time delivery.

Wholesale Finished Products

We supply bulk quantities of popular floss pick products with ample inventory and competitive pricing, enabling channel partners to quickly replenish stock and meet end-user demand.

Popular Floss stick Manufacturing Service

Floss with stick

Floss with Stick, an innovative oral care product, combines Floss thread made of UHMWPE ultra-high molecular weight polyethylene fiber and Stick made of HIPS food-grade plastic to bring you a brand new oral cleaning experience.The Floss thread is made of bullet-proof vest fiber with high strength and friction characteristics, with a fine and smooth rounded thread that does not break up, and an ergonomically shaped shank to save effort; the curved hook at the end can be used as a toothpick.

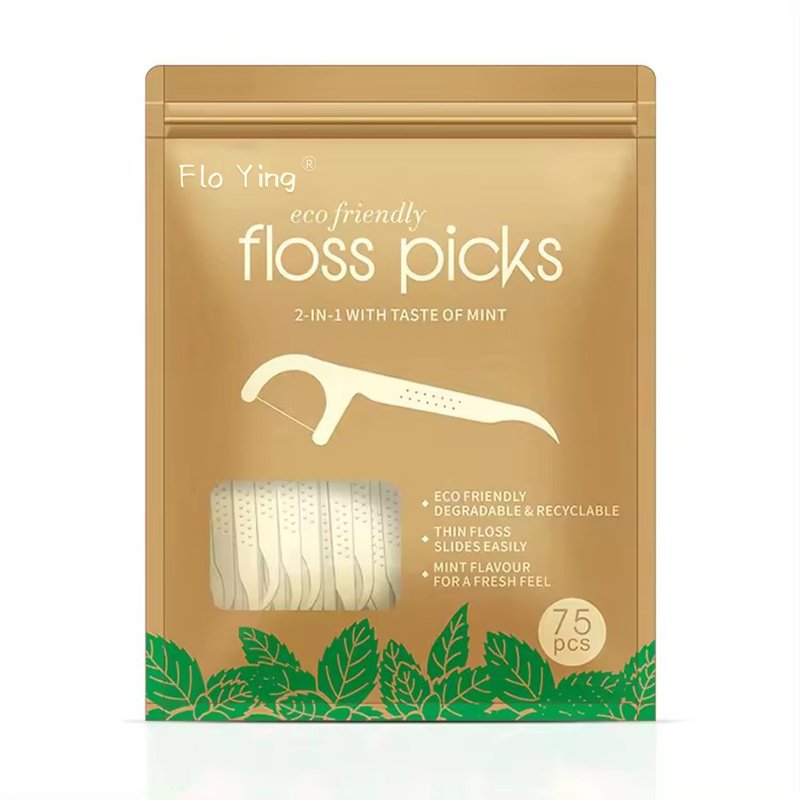

Biodegradable floss stick

Biodegradable Floss Stick, an environmentally friendly oral care product, combines UHMWPE UHMWPE fibers made of Floss thread and PLA biodegradable corn starch made of Stick to bring you a new oral cleaning experience.Floss thread is made of bullet-proof vest fibers with high strength and friction characteristics, fine and smooth round threads that do not fall apart. The round thread does not break and does not fall apart, the handle conforms to the ergonomic grain to save energy; the curved hook design at the end can be used as a toothpick. The product adds mint/fruit factor to remove food residue and freshen breath. Adult models are usually mint flavor, children's models are mostly fruit flavor.

Get a one-stop solution

Phone: 0591-85104888

Email: peter@ruiqigo.com

Address: No.27 Yangting Road, 3TOP Industrial Park, Taiyuan Village, Chengfeng Town,Yongtai County, Fuzhou, Fujian, China, 350700

Privacy:

As with all of our clients, confidentiality remains of paramount importance to demonstrate our commitment to customer service. You can fill out the application form with confidence that your form will only be used for quote purposes.

Ready to get started?

If your project requires more immediate assistance, please give us a call or email and we will respond to you as quickly as possible.

Thanks for connect with us. Ask me anything.

Capabilities of 3TOP Floss stick Manufacturer

-

Sterilization room

-

Raw material warehouse

-

Batching room

-

Dispensing room

-

Filling line

-

Carton coding

-

Packaging line

- Working Procedure

- Function Characteristics

Dressing, hand washing, and drying, into the air shower room disinfection.

The clean room ensures that every employee entering the room meets the operating standards through strict sterilization steps.

- Working Procedure

- Function Characteristics

1. Material Purchase

All raw material applications always have a requisition form, the warehouse manager according to the requisition form for verification according to the monthly material requirements of the master plan for the system application.

2. Material into the warehouse process

Warehouseman according to the procurement contract and delivery list for inventory, verification, material placed in the area to be inspected, and in a timely manner to do a good job of material identification, labeled to be inspected. Then warehouseman according to the actual number of input computer ERP system prints out the receipt of materials signed by the receipt of joint delivery or purchaser and, at the same time, the inspection of the joint to the inspector of the material the factory inspection.

The factory inspector received the inspection sheet and the timely inspection of the materials in the batch.

The material acceptance of qualified, the inspector in the receipt of materials on the signature to confirm; the inspector will be qualified and non-qualified products were labeled, clearly distinguishable.

Materials placed in the designated partition location.

1. Safe and stable reserve

Raw material warehouses can provide safe and stable material reserves for production and ensure the stability and continuity of enterprise production capacity. The distribution of raw materials in the LS warehouse requires flexibility and timely supply. When the production line needs raw materials, the requirements of raw material reserves are sufficient, to be able to timely deployment and supply to the production line, to meet the production needs.

2. Ensure the quality of production

Raw material warehouses can ensure the stability and reliability of the quality of raw materials needed for production so that enterprises in the production chain to ensure product quality and competitiveness.

3. Reduce production costs

Raw material warehouses in ensuring product quality at the same time, can reduce production costs, and improve corporate profitability and market competitiveness. Characteristics: Adopting XXX method to make the stored materials free from moisture, heat, damage, and so on. Set up an anti-theft alarm system, fire alarm equipment, fire prevention measures, and other measures for the warehouse to ensure the safety and stability of raw material reserves.

- Working Procedure

- Function Characteristics

1. Receive the outgoing task list

According to the production plan and recipe list to prepare the required materials.

2. Batching

Accurately weigh the components and record the data; add the matched materials into the mixing equipment according to the specified order and monitor the mixing process.

3. Cleaning

Clean up the site in time after completing the dosage, keep the environment neat and clean.

4. Update the inventory

At the same time, update the real-time status of the inventory of material consumption, to ensure that the production is carried out smoothly.

Responsible for accurately batching, weighing, and mixing raw materials to ensure consistency and accuracy of each recipe, aiming to ensure accurate batching of materials and efficient inventory management.

- Working Procedure

- Function Characteristics

1. Equipment sterilization

Sterilize the equipment before operation to ensure the safety of production.

2. Mixing

According to the formula, put different raw materials into the stirring reaction pot for mixing, after stirring and other processing, make all kinds of raw materials reach the condition of a chemical reaction.

3. Heating and cooling

The mixture with an adjusted formula is heated and cooled, through heating, it can make certain ingredients in the mixture dissolve and react better, and strengthen the stability of the product.

4. Pumping

The processed semi-finished products will be pumped into the assembly line after inspection to make the next step of molding and packaging.

Function: Make semi-finished products.

Features:

1. Reduce airborne dust

The clean room uses high-efficiency purification systems, operating tables, floors, walls, and other materials that can effectively reduce airborne dust. By purifying the air, it can ensure that the chemical components and microorganisms are fully protected during the production process, preventing external particles from mixing into the products, and ensuring the high quality and stability of the products.

2. Prevent biological pollution

In the production process, too many microorganisms can easily cause fermentation, spoilage and other problems in the production process. However, in the clean room, disinfection lamps, differential pressure control systems, UV lamps and other equipment will be used, which can effectively kill microorganisms, and can prevent pollutants from the outside from entering the workshop.

3. Purify the air in the workshop

Clean room, often using air purification equipment and tightly closed structure, in order to purify the air in the workshop, and raise the pressure in the workshop. By isolating the workshop from the outside world, the cleanliness of the production process is ensured.

- Working Procedure

- Function Characteristics

1. Material preparation

Insert the container to be filled into the work box and make sure the liquid storage barrel is full of liquid to be filled.

2. Power supply connection and startup of the filling machine

Turn on the external power supply, set the machine power switch to ON position, and the power indicator light will be on to indicate that the power supply is on.

3. Filling volume adjustment

According to the total amount of each bottle filling, adjust the screws on the crank to ensure that the amount of liquid flowing out of each filling head is the set amount.

4. Filling speed control

Rotate the knob of the filling speed control board to the appropriate position, and then toggle the switch on the filling speed control board to the open position to control the filling speed.

5. Start filling

Close the filling speed regulator board switch, reset the total metering pump output pipe, and then toggle the filling speed regulator board switch to the open position, the total metering pump starts to work, and enters into the liquid dispenser through the total metering pump output pipe, and the liquid is dispensed through the liquid volume micro-adjustment and outflow from the syringe to complete the filling.

Function: Filling the semi-finished products with the set amount of filling and the form of packaging, automatically filling the semi-finished products accurately into the corresponding packaging, and then transferring them to the next process by conveyor belt.

- Working Procedure

- Function Characteristics

Spray the carton with the corresponding barcode through the inkjet printer

Function: Non-contact marking of the products, clear and fast.

- Working Procedure

- Function Characteristics

1. Preparation

Before starting the packaging, you need to prepare the required packaging materials and equipment, such as cartons.

2. Product input

The products are transported from the upstream production line to the assembly line packaging line through the conveyor belt.

3. Packaging operation

The products are sleeved, shrunk, coded and boxed.

4. Packing and sealing

Finally, the packed products are sealed.

Function: Packaging of semi-finished products into a complete product. Characteristics: One-way operation, strict process, fast speed.

3TOP Floss stick Factory Features

-

Complete Workshop and Processes

Complete Workshop and Processes

3TOP has advanced production facilities and complete manufacturing processes to ensure that every step from raw materials to finished products meets the highest standards.

-

R&D Strength

R&D Strength

3TOP's R&D team cooperates with renowned universities and laboratories to continuously promote product innovation and technological advancement.

-

Purely Personalized Customization

Purely Personalized Customization

With a professional R&D team, we provide full-process customization services from testing to production to ensure the uniqueness and competitiveness of our products.

-

Lower MOQ

Lower MOQ

Flexible production strategy to meet diversified needs from small to large quantities.

-

Quality Control

Quality Control

Strict quality control process at the source factory to ensure product consistency and reliability.

-

Climate Adaptability

Climate Adaptability

Customized products for different regional climate characteristics to meet the needs of the global market.

-

Production Apacity and Scalability

Production Apacity and Scalability

Large-scale production capacity and the ability to quickly respond to market changes and expand production capacity.

-

Environmentally Friendly Packaging Materials

Environmentally Friendly Packaging Materials

Use 100% biodegradable and recyclable environmentally friendly materials to minimize the impact on the environment.

-

Fast Sample Service

Fast Sample Service

Provide free samples and promise to send them out quickly within a week, far exceeding the industry standard.

-

Customized Packaging Design

Customized Packaging Design

Provide personalized packaging design and suggestions to enhance product market appeal.

3TOP Floss stick OEM/ODM Advantage & Benefits

-

1

Customization of various specifications and styles

3TOP provides a variety of dental floss sticks specifications and styles, including C-shaped, F-shaped, Y-shaped and other shapes, which can be customized according to customer market needs to meet the preferences of different consumer groups. -

2

Strong production capacity and delivery guarantee

3TOP has large-scale modern production equipment with a daily production capacity of hundreds of thousands of pieces. It can quickly realize the production of large-scale OEM/ODM orders, while strictly controlling the delivery cycle to ensure that the project is delivered on time. -

3

Selection of environmentally friendly materials

We use food-grade materials such as PP, PE, and various high-strength nylon or PE wires in the production of dental floss sticks to ensure that the products are environmentally friendly, safe and meet export standards, and ensure the health and comfort of end users. -

4

International market compliance experience

3TOP has rich business experience in many major markets around the world (such as North America, Europe and Southeast Asia), ensuring that products meet the quality and safety standards of various countries, such as FDA, CE, etc., effectively helping customers complete international market compliance requirements. -

5

Strict quality control system

We have a complete quality management and control process. From raw material procurement to finished product delivery, 3TOP implements multiple tests to ensure that each batch of dental floss sticks meets ISO and GMP standards, reducing the defect rate and making brand customers more assured. -

6

Innovative design and function development

In addition to providing basic dental floss stick customization services, 3TOP also supports innovative designs, including multi-functional dental floss stick designs, such as dual-use models with toothbrush heads, to help brands meet the functional needs of different market segments. -

7

Flexible customization services

3TOP's OEM/ODM services provide customers with flexible customization options. Whether it is small-scale trial production or large-scale production, it can be flexibly adjusted and can respond quickly according to market feedback to improve brand response speed. -

8

Mature private label support

We provide customers with a one-stop solution from product design, packaging to finished product production, and fully support brand private label customization. Customers can launch products with unique brand logos in a short time to enhance market competitiveness. -

9

Sustainability and green packaging solutions

3TOP actively responds to environmental protection trends and provides customers with degradable and environmentally friendly packaging options, which conforms to the green consumption concept of modern consumers and helps brands establish a good image in the field of environmental protection. -

10

Ingredients and Equipment Certification

We use high-quality PE wire with good tensile strength and durability. All materials meet international environmental certification standards to ensure that customers' brand reputation and market security are stable during OEM/ODM production.

Certificates

Start your Floss stick bussiness with our support

-

Andrew Wilson

Having partnered with 3TOP for our dental floss production, I can confidently say it's been a collaboration that's as smooth as the floss itself. Their custom processing service has been nothing short of exceptional, allowing us to offer our customers a product that's both effective and enjoyable to use.

The team at 3TOP truly understands the nuances of dental care, and it shows in the quality of their work. They've been incredibly responsive to our needs, providing us with floss that's just right in terms of texture and packaging. Their attention to detail has ensured that every spool of floss meets the high standards we set for our brand.

What I appreciate most is their commitment to innovation. In a market saturated with options, 3TOP has helped us stand out with their creative solutions and fresh ideas. Their ability to adapt to our vision and bring it to life has been truly impressive.

Moreover, their customer service is top-notch. The 3TOP team is always ready to assist, providing clear communication and support throughout the production process. It's this level of dedication that has made our partnership a success.

In essence, 3TOP's professionalism, innovative approach, and exceptional service have made them a valued partner for our dental floss line. We're looking forward to continuing our collaboration and creating more products that enhance our customers' oral health routines. -

Claire Thompson

Working with 3TOP has been an experience that's left a lasting impression on our dental floss brand. Their custom manufacturing service has been instrumental in bringing our vision to life, offering a product that's both high-quality and tailored to our specific requirements.

The level of care and precision that 3TOP puts into every spool of floss is evident, and it's this dedication that has allowed us to provide our customers with a dental floss that's gentle on the gums yet effective in cleaning between teeth. Their understanding of the importance of dental hygiene products is reflected in the thoughtful design and manufacturing process.

One of the standout aspects of our collaboration has been their flexibility. Whether it's adjusting the thickness of the floss or the packaging design, 3TOP has been able to accommodate our requests with ease, ensuring that the final product aligns perfectly with our brand's ethos.

Moreover, their customer service is exemplary. The team at 3TOP is always on hand to provide assistance and guidance, making the entire production process a breeze. Their proactive approach to problem-solving has been invaluable to us.

In summary, 3TOP's commitment to excellence, their innovative spirit, and their customer-centric service have made them a standout partner in the dental floss manufacturing industry. We're thrilled with the results and eagerly anticipate what the future holds for our partnership.

Guess you also want to ask

-

What material is used in the floss manufactured by 3TOP?

The major dental floss produced by 3TOP mainly uses two high-quality materials: high-strength Nylon wire and PE wire. These two materials are widely used in the production of dental floss products because of their excellent performance and safety and meet the quality and hygiene standards of many countries.

The first is nylon filament, a common dental floss material, widely used in high-quality dental floss products due to its fine elasticity and toughness. Normally, the dental floss made by the nylon thread has very good resistance to stretching and a surface that is very fine, which passes between tight teeth very smoothly and decreases gum irritation. Further, the nylon material can be made almost free of burrs and not broken filament, so it is improved during use and most often is suitable for users with oral sensitivity.

Moreover, PE wire, that is, Polyethylene material, is very durable and wear resisting. The extra advantage of PE floss is that its surface is relatively soft, which is less injurious to the gum tissue while cleaning between teeth. It has good biocompatibility and reduces residue and plaque between teeth effectively so that cleaning is more thorough. Besides, low hygroscopicity of PE materials helps retain high strength and durability in humid environments, which also includes the oral cavity.

3TOP may, in customer customization services, use other environmentally friendly materials or higher-end composite materials. For instance, flossing products may use surface materials coated with specific formulas for further improving antimicrobial properties or increasing cleaning effectiveness. The above is to meet the varied markets’ requirements.

Materials for dental floss that is selected by 3TOP are generally imporiazedition and have passed not only food grade standardbutions of safetynot only food-grade safety standards but also corresponding to multiple international certifications such as FDA/CE and so on to guarantee relevant clients in the global market. -

Does 3TOP offer floss in different sizes and specifications?

Yes, 3TOP provides many kinds of dental floss picks’ specifications and sizes to cater to different markets and consumer needs. According to the product introduction on the official website, 3TOP can not only provide final B customers’ products with a variety of shapes, like C-shaped, F-shaped, Y-shaped, and other floss pick designs, but also customize them based on the specific requirements of the customers. In terms of handle length, wire thickness, or other functional design, 3TOP provides flexible options.

Besides, 3TOP supports OEM/ODM customization services; customers can choose different sizes of dental floss lengths and wire diameters. According to the market demand, choose different dental floss specifications. For instance, thin dental floss is appropriate for cleaning tight gaps between teeth, whereas thick dental floss is ideal for users with large gaps between teeth. This kind of diversified specification design helps brands cater to the needs of different groups of consumers.

This way, 3TOP can better assist brands in expanding their competitiveness in multiple markets around the world with dental floss picks of different specifications. -

Does 3TOP offer customized packaging for dental floss?

Yes, 3TOP offers dental floss products with customized packaging. It’s part of OEM/ODM service. 3TOP can design various forms of packaging solutions for dental floss according to the requirements of the customer's brand positioning and market demand. This helps create a unique brand image for customers.

For instance, 3TOP can according to demand provide a series of packaging designs for packaging, including packaging material, color, printing pattern, logo customization, etc., so that the product of dental floss is more recognizable in the market and more in line with the positioning of the brand. In addition, 3TOP provides a variety of environmentally friendly packaging—important in today's market focused on sustainable packaging (packaging sustainability)—that helps companies create a positive image with their environmentally conscious consumers.

On the whole, 3TOP’s custom packaging services to brand customers help them launch dental floss products that are more competitive, improving product aesthetics and functionality and at the same time assuring the enhanced value of a brand’s differentiation positioning on the market. -

How does 3TOP ensure the quality of our products during the floss production process?

3TOP adopts a series of strict quality control measures to ensure the high quality and consistency of its dental floss products during the production process. These measures are implemented throughout every link of production, from raw material selection to final product packaging, and every step is strictly monitored and reviewed. The following are the main ways 3TOP ensures product quality during the production process:

1. Carefully selected and tested raw materials

Raw materials are the basis of product quality. 3TOP uses strictly selected high-quality raw materials in dental floss production. For example, 3TOP uses high-strength nylon filaments and PE filaments, which are subject to strict raw material testing such as strength, abrasion resistance, and tensile resistance before entering the production line. This ensures that the final dental floss can not only effectively clean teeth but also has sufficient durability and comfort.

2. Advanced manufacturing process and equipment

3TOP adopts advanced production equipment and processes to ensure precision and stability. During the production process, automated equipment is used to manufacture dental floss and dental floss sticks to reduce human errors. 3TOP also introduced an automatic detection system, which can monitor production parameters in real-time to ensure that the size, shape, and performance of the product are stable and consistent.

3. Strict production environment control

To ensure the safety and hygiene of its products, 3TOP strictly adheres to international hygiene standards and controls the production environment in its production plants. The production workshop is dust-free, sterile and ISO-certified, which reduces the impact of external contaminants on the products. At the same time, all production personnel will be subject to strict hygiene management when entering the factory to prevent any unhygienic hidden dangers caused by any artificial factors.

4. Comprehensive quality inspection system

3TOP uses a comprehensive quality inspection system (Quality Control System) to conduct multi-step inspections on products. Including but not limited to:

Tensile test: Ensure that the strength of the dental floss meets the required standards to avoid breakage during use.

Abrasion resistance test: Evaluate the durability of the dental floss in actual use to ensure that it will not wear or fail during long-term use.

Surface smoothness test: Ensure the smoothness of the dental floss to reduce possible irritation and damage to the gums.

Sanitary qualification test: Check whether the product has met the necessary hygiene standards to ensure that the product is safe and non-toxic, usually including certification of international standards such as FDA and CE.

5. Continuous factory audits and improvements

3TOP conducts regular audits and improvements to its production system, and all production links and control measures need to be professionally certified. 3TOP's factories have relevant international certifications, such as ISO 9001 quality management system certification, to ensure that the entire production process meets strict international standards. Each batch of product samples will also undergo a final quality inspection before leaving the factory to maintain the consistency and high standards of all products leaving the factory. -

What is 3TOP's floss production capacity and can it meet the demand of large orders?

3TOP has a very strong production capacity for big order requirements. Public information and production capacity description for the company states that 3TOP has advanced automation equipment and large-scale production lines along with strict management processes, which enable them to efficiently complete large-scale orders. In essence, the following points enumerate the advantages of 3TOP in dealing with large-scale orders:

1. Large-scale production facilities

The company's factory is located in Ningbo, which is one of China's important industrial production bases. Large-scale automated production equipment and advanced technical processes are adopted in the factory, productive efficiency is very good. There are several production lines in the factory: several types and specifications of dental floss products can be produced at the same time. When orders are large, with such production facilities, the company can guarantee that production tasks are accomplished on time without giving up product quality.

2. Equipment of the Latest Automation Level

3TOP employs state-of-the-art, highly automated equipment that enhances production speed adjoined with the stability and consistency of the production process greatly. This kind of highly automated equipment shortens the production cycle and increases output significantly, allowing the company to deal with large orders while reducing errors and delays introduced by manual operations.

3. Flexible production capacity

Depending on specific needs, 3TOP is able to flexibly adjust production lines to produce dental floss products of different specifications and quantities. Whether it is a standard product or a customized product, 3TOP can adjust production plans in a timely manner through flexible resource allocation and production management systems to meet the needs of large orders in a short period of time.

4. High production capacity values

Although the specific output may vary depending on the type and specification of the product, 3TOP is usually able to provide millions of units of dental floss products to major customers and international markets, or even more. This enables 3TOP to quickly meet large orders from global brands and their distribution networks.

5. Focus on large-volume orders from B-end customers

As an OEM/ODM supplier, 3TOP focuses on providing dental floss solutions for brands and large wholesalers. Therefore, their production processes, supply chain management, and delivery capabilities are designed to cope with large orders. The long-term experience of cooperating with international brands has also made 3TOP more handy when handling large orders. Whether it is product production, packaging or delivery logistics, there are mature processes and solutions to ensure timely delivery.

6. Global Supply Chain and Logistics Management

In addition to production capabilities, 3TOP has established an efficient supply chain management system that can ensure the continuous supply of raw materials and coordinate a fast logistics system. With these global procurement and distribution service capabilities, the company can ensure that after mass production, the products are delivered to customers around the world quickly and safely. This is especially critical for handling urgent large-volume orders.

Summary:

3TOP has sufficient production capacity to cope with large-scale orders. With modern production equipment, flexible factory management systems, and a global supply chain system, 3TOP can efficiently meet the mass production needs of domestic and foreign customers. If your business requires large quantities of customized or standard dental floss products, 3TOP is fully capable of ensuring on-time delivery of high-quality products. -

What kind of testing do 3TOP's floss products go through?

3TOP's dental floss products go through a series of rigorous tests to ensure that they meet quality, safety and performance requirements. These tests are carried out throughout the product development and production process to ensure that each dental floss meets the highest standards. The following are the main types of tests 3TOP performs on dental floss products:

1. Tensile Strength Test

The strength of dental floss is key to ensuring that it does not break during use. 3TOP uses a tensile testing machine to test the tensile strength of dental floss to ensure that the wire can withstand the tension when sliding between teeth without breaking easily. This is an important test related to product reliability and user experience.

2. Abrasion Resistance Test

Dental floss often slides back and forth between teeth, so it is necessary to evaluate its abrasion resistance. By simulating the friction during normal use, 3TOP ensures that the dental floss will not wear out prematurely or lose its effectiveness. This test helps to confirm the durability of the dental floss, especially in high-frequency use, without affecting the cleaning effect due to wear.

3. Surface Smoothness Test

The surface smoothness of the dental floss is directly related to the user experience. Too rough dental floss may irritate the gums or cause discomfort, so 3TOP tests the surface of the product to ensure that the dental floss is smooth enough when used, which can effectively clean the residue between the teeth without scratching the gums or teeth.

4. Hygiene and safety testing

Microbial contamination detection: As an oral cleaning tool, dental floss must ensure that it does not contain any harmful microorganisms. 3TOP conducts hygiene testing on each batch of products, including monitoring of microbial contaminants in materials and final products to ensure that the product does not introduce bacteria or other substances that may endanger oral health during use.

Toxicological Testing: Any product that comes into contact with the mouth must undergo toxin-free testing to ensure that its materials are safe and will not have harmful effects on the human body. The raw materials used by 3TOP (such as nylon, PE wire, etc.) are subject to chemical composition analysis and toxin-free testing to ensure that they meet the regulatory requirements of major markets such as the United States and Europe, such as FDA and CE certification.

5. Durability Test

In order to evaluate the long-term performance of dental floss, 3TOP will conduct test scenarios that simulate long-term use to test whether the dental floss can maintain its initial performance after each use. Although dental floss is a disposable product, the duration of performance in a reusable scenario is still of certain value to some customers.

6. Shape and Dimension Testing

This type of testing is used to ensure that the size, thickness, and shape of dental floss products are consistent with design specifications. For example, the thickness of the dental floss needs to take into account whether it is suitable for users with different tooth gaps and whether the design of the dental floss stick is comfortable and functional enough during use. 3TOP conducts regular shape testing on dental floss to ensure the dimensional accuracy of the product.

7. Moisture Resistance Test

Some dental floss may be used in special treatments containing peppermint essential oils or antibacterial agents, which require moisture absorption and material compatibility testing. 3TOP will conduct humidity or liquid absorption tests on these special-function dental floss to ensure that it does not dry out too much or become unstable after absorbing moisture.

8. User Experience Testing

Although it is not a standard testing link for every dental floss product, some customized or new dental floss products will be tested by actual users to obtain usage feedback. By evaluating real user feedback data, 3TOP can improve the design and function of dental floss to ensure that it meets the expectations of consumers.

9. Environmental protection and sustainability testing

For some dental floss produced with sustainable materials, 3TOP will conduct environmental protection and biodegradability tests. With the improvement of global environmental awareness, more and more consumers and brand customers require their products to be environmentally friendly, so 3TOP conducts a comprehensive assessment of the entire life cycle of the product, including the environmental impact of production materials, use and disposal processes.

Comprehensive verification

After passing the test, 3TOP will continue to conduct a final inspection (Final Inspection) before batch shipment to ensure that each batch of dental floss products meets the core standards. This multi-level quality control ensures that 3TOP's dental floss products reach the best level in terms of strength, durability, safety and user experience, and meet various quality requirements. -

Are 3TOP's floss products have competitively priced in the market?

Yes, 3TOP’s dental floss products are very price competitive in the market. 3TOP is able to offer high-quality products while maintaining competitive prices thanks to several key factors. Here’s why 3TOP is able to offer competitive prices compared to other manufacturers:

1. Advantages of economies of scale

As a mass producer, 3TOP has significant economies of scale. Due to its strong production capacity and efficient automated production system, 3TOP is able to reduce unit production costs through mass production. This allows them to provide more competitive pricing to customers, especially OEM/ODM customers or large-scale retailers who need to purchase in large quantities.

2. Vertical integration and efficient supply chain

3TOP has a highly vertically integrated production process, from raw material procurement to manufacturing to packaging, which is almost entirely managed in-house, reducing reliance on third-party suppliers. This vertical integration model helps the company reduce outsourcing costs, simplify and speed up the production process, further reduce overall costs, and be able to reflect these savings in product prices. At the same time, long-term and stable supply chain management allows 3TOP to purchase raw materials at lower costs, thereby further reducing the cost of final products.

3. Cost advantages of manufacturing in China

Located in Fujian, China, 3TOP is uniquely positioned to enjoy the low-cost production advantages of China as a global manufacturing center. China's production costs (such as labor and raw materials) are relatively low, and it has complete supporting infrastructure and logistics services, which further improves production and transportation efficiency. In addition, the Chinese local market also provides 3TOP with a series of high-quality, low-cost production resources, which is very helpful for the company to control costs.

4. Application of automation technology

3TOP has extensively introduced advanced automated production equipment, which significantly reduces reliance on labor and reduces human errors in the production process, thus improving production efficiency. This further reduces the production cost per unit of product and enhances overall competitiveness. The introduction of automation also shortens the production cycle, enabling large-volume orders to be completed in a short period of time, enhancing market competitiveness.

5. Internal R&D and customized solutions

3TOP has a strong in-house R&D team that can quickly optimize and innovate production processes. This not only ensures the high quality of products, but also reduces the cost of developing innovative products. The company can also provide customized dental floss products and solutions based on customer needs to meet the unique needs of different markets. Through a more efficient customization process, 3TOP is able to provide flexible and economical price plans and reduce the additional costs of customization.

6. Price competitiveness in global markets

3TOP has set a competitive price structure for global markets such as North America, Europe and Asia Pacific. The company has long-term cooperation with customers in many regions around the world and is very familiar with the price trends and customer needs of the global market. Therefore, it can accurately grasp market expectations and ensure reasonable pricing from a fiercely competitive global perspective. At the same time, 3TOP's efficient export services reduce intermediate links and further improve the cost performance in the global supply chain.

7. Volume discounts and offers

For customers who place large orders, 3TOP usually provides volume discounts or special preferential policies, which allows large-volume customers to enjoy more favorable prices. Through such a discount mechanism, 3TOP can effectively control the price of single products when facing large orders and long-term partners, helping customers reduce overall procurement costs, thereby improving price competitiveness.

8. Economics of environmentally friendly and sustainable packaging

3TOP also provides economical and environmentally friendly packaging solutions that comply with environmental trends without significantly increasing packaging costs. This balance point allows the company to meet the dual needs of customers for environmental protection and economy at the same time, and further enhance market competitiveness when facing emerging green environmental protection trends and market hotspots pursuing high cost performance.

9. Stratified marketing strategy

3TOP's dental floss products cover many different market levels, from basic mass products to high-end customized or high value-added dental floss products. Different series of products have different pricing strategies and target different target markets. Such flexible price stratification can help 3TOP gain competitive advantages in multiple market segments and meet the budget needs of different customer groups.

10. Long-term partner program

3TOP values long-term cooperation and maintains long-term cooperative relationships with customers who have stable and large order demands, usually providing more flexible price negotiation space. By formulating long-term cooperation contracts, customers can enjoy more price concessions and ensure cost stability and controllability over a longer period. -

What is the lead time for 3TOP's dental floss products?

3TOP's dental floss products generally take between 15 and 60 days to deliver, depending on the type of order and the production schedule at the time:

Standard products (in stock): delivery time is approximately 15 to 30 days.

Customized orders: delivery time is approximately 30 to 45 days.

Large volume orders: delivery time is approximately 30 to 60 days, depending on the specific situation.

Urgent or expedited orders: can be expedited, with a delivery time of approximately 15 to 25 days.

Before ordering, it is recommended to communicate in detail with the 3TOP team to ensure that the delivery time matches your needs and discuss logistics options at the same time. If the order volume is large or special customization is required, it is also possible to arrange production plans in advance to ensure that the delivery time is within the customer's expectations. -

What after-sales services does 3TOP provide?

1. Quality Assurance

3TOP adheres to strict quality standards and provides customers with a certain period of product quality assurance. In most cases, the quality assurance includes:

If the product has quality problems such as breakage, packaging damage or functional defects within the specified shelf life, 3TOP will provide customers with free replacement or partial/full refund.

The specific quality assurance conditions usually vary according to the provisions in the contract and the type of product.

2. Sample support

In the case that customers need to iterate new products or evaluate new and improved products, 3TOP can provide free or discounted samples according to customer requirements. At the same time, 3TOP will further optimize the sample quality inspection and other links based on customer feedback to ensure that the product meets customer standards and market needs.

3. Rapid complaint feedback mechanism

Customer complaint handling is an important part of 3TOP's after-sales service. If customers are not satisfied with the products they received, or there are problems such as product defects or transportation damage, customers can quickly file a complaint. 3TOP will arrange a special after-sales service team to respond to customers and handle problems within 24 to 48 hours. The specific complaint process includes:

Collect detailed product information (such as batch number, production date, etc.) and problem description.

Reissue products or replace them as appropriate.

For complaints related to packaging or product design, 3TOP's technical team and quality inspection team will conduct a joint analysis to determine the cause of the problem and prevent it from happening again in the future.

4. Material tracking and feedback mechanism

3TOP strictly manages and tracks the production batches of products and the materials used. If a customer has a product problem, 3TOP can quickly trace the corresponding production process and the raw materials used to quickly find the root cause of the problem and make timely adjustments. This is very helpful for maintaining product consistency and high quality.

5. Regular customer return visits

3TOP's customer service team will regularly return visits to customers to understand product usage and customer satisfaction, especially for long-term cooperative large customers. Through return visits, 3TOP can collect information about product performance, whether the packaging is suitable, and the reaction of the product in the market.

During the customer return visit, if the customer raises new product requirements or improvement suggestions, 3TOP will promptly pass these feedback to the R&D team in order to make improvements in future batches and increase customer satisfaction.

6. Technical support

For customers who need customized products or special packaging, 3TOP provides comprehensive technical support and after-sales consulting services. Customers can communicate directly with the 3TOP technical team after receiving the product to ensure that the product meets the customization requirements. If there are any adjustment requirements, 3TOP will optimize it in subsequent production.

If customers encounter any technical problems in product specifications, usage methods or storage, they can also get detailed answers and suggestions.

7. Logistics problem handling

If logistics damage or product loss occurs during product transportation, the 3TOP after-sales service team will immediately negotiate with the logistics supplier to solve the problem and help customers deal with compensation and reissue issues. Depending on the specific situation, 3TOP will also re-ship to ensure that customers can receive qualified products on time as promised.

8. Regular product upgrades and suggestions

As a professional manufacturer of dental floss products, 3TOP will regularly upgrade its product line based on market trends and technological advances. While improving the efficacy, materials and user experience of products, 3TOP will also proactively recommend new models or more advantageous products to customers. At the same time, they can also provide customers with market advice to help customers stay competitive in the fiercely competitive market. -

Does 3TOP adopt environmental protection measures in the production process?

3TOP has adopted a number of environmental protection measures in the dental floss production process, from environmentally friendly material selection to production process optimization, to fully promote sustainable development. The company uses biodegradable and recyclable materials, reduces traditional plastics and adopts natural coatings. At the same time, 3TOP reduces energy consumption and waste generation by introducing energy-saving equipment, optimizing production processes and waste management. In addition, the company strictly manages the supply chain to ensure that the entire production process meets environmental standards. In terms of packaging design, 3TOP reduces the use of disposable plastics and introduces a design with replaceable dental floss cores. In order to fulfill its environmental commitment, 3TOP has passed environmental certifications such as ISO 14001, actively developing sustainable products to meet market demand and promote environmental awareness.

2.jpg)

1.jpg)